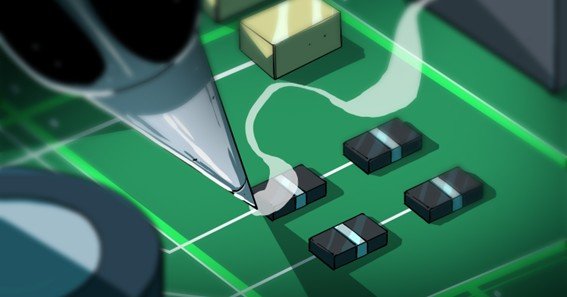

Achieving flawless solder joints is critical for any electronics or metalworking project, and the fk iron flux max is here to help. This high-performance soldering flux is engineered to improve solderability, reduce oxidation, and ensure strong, durable connections.

In this article, we’ll explore the key features, benefits, and usage tips for FK Iron Flux Max, along with answers to some of the most frequently asked questions.

What Makes FK Iron Flux Max Unique?

Superior Soldering Performance

FK Iron Flux Max is designed with a powerful formula that excels in removing surface oxides from metal surfaces, allowing solder to flow smoothly and create robust joints. Its advanced chemical composition ensures:

- Effective Oxide Removal: The flux cleans and prepares metal surfaces for soldering, minimizing defects.

- Enhanced Solder Flow: Its formulation promotes excellent wetting and spreading of solder, leading to stronger connections.

- Reduced Residue: When used properly, the flux leaves minimal residue, ensuring that the final assembly remains clean and reliable.

Versatility Across Applications

Whether you’re working on printed circuit boards, wiring harnesses, or other electronic assemblies, FK Iron Flux Max is versatile enough to deliver consistent performance. It’s suitable for both manual and automated soldering processes, making it a preferred choice for hobbyists and professionals alike.

Easy Application and Cleanup

The flux is available in user-friendly forms, such as liquid or paste, allowing for easy application. Its low corrosivity ensures that it’s safe for a variety of components, and cleanup is straightforward, reducing post-soldering maintenance.

FAQs

Q1: What is FK Iron Flux Max?

A1: FK Iron Flux Max is a high-performance soldering flux designed to improve the quality and reliability of solder joints by effectively removing oxides and promoting smooth solder flow.

Q2: How does FK Iron Flux Max enhance soldering?

A2: It works by cleaning metal surfaces of oxides before soldering, which allows solder to bond more effectively. This results in stronger, more durable joints with minimal defects.

Q3: What types of projects are best suited for using FK Iron Flux Max?

A3: FK Iron Flux Max is ideal for a wide range of applications, including electronics assembly, PCB soldering, and general metalwork. It’s suitable for both manual and automated soldering processes.

Q4: How should I apply FK Iron Flux Max during soldering?

A4: Apply a thin, even layer of the flux on the metal surfaces before soldering. For best results, follow the manufacturer’s guidelines regarding temperature and timing to ensure optimal solder flow and joint quality.

Q5: Are there any safety precautions I should take when using FK Iron Flux Max?

A5: Yes, always use the flux in a well-ventilated area and wear appropriate personal protective equipment (PPE) such as gloves and safety glasses. Follow all manufacturer instructions and local safety regulations when handling and disposing of the flux.

By incorporating fk iron flux max into your soldering process, you can achieve superior joint quality and reliable performance for your projects. Its advanced formula, versatility, and ease of use make it an essential tool for anyone serious about high-quality soldering outcomes.